In a world powered by electricity, there’s no reason to be shocked that electrical safety is the number one priority. When it comes down to keeping our commercial electricians safe, what are the most important factors at Rogers Electric?

Training and Awareness

It is crucial for commercial electricians to undergo safety training. This is to be aware of the protocols set in place by their company and understand the risks involved. At Rogers Electric, we are committed to the safety of our technicians. To us, they are not just employees, but a part of our family. We want to make sure every member of our family to return home safely at the end of each work day. The goal is to establish and maintain a safe and quality work environment.

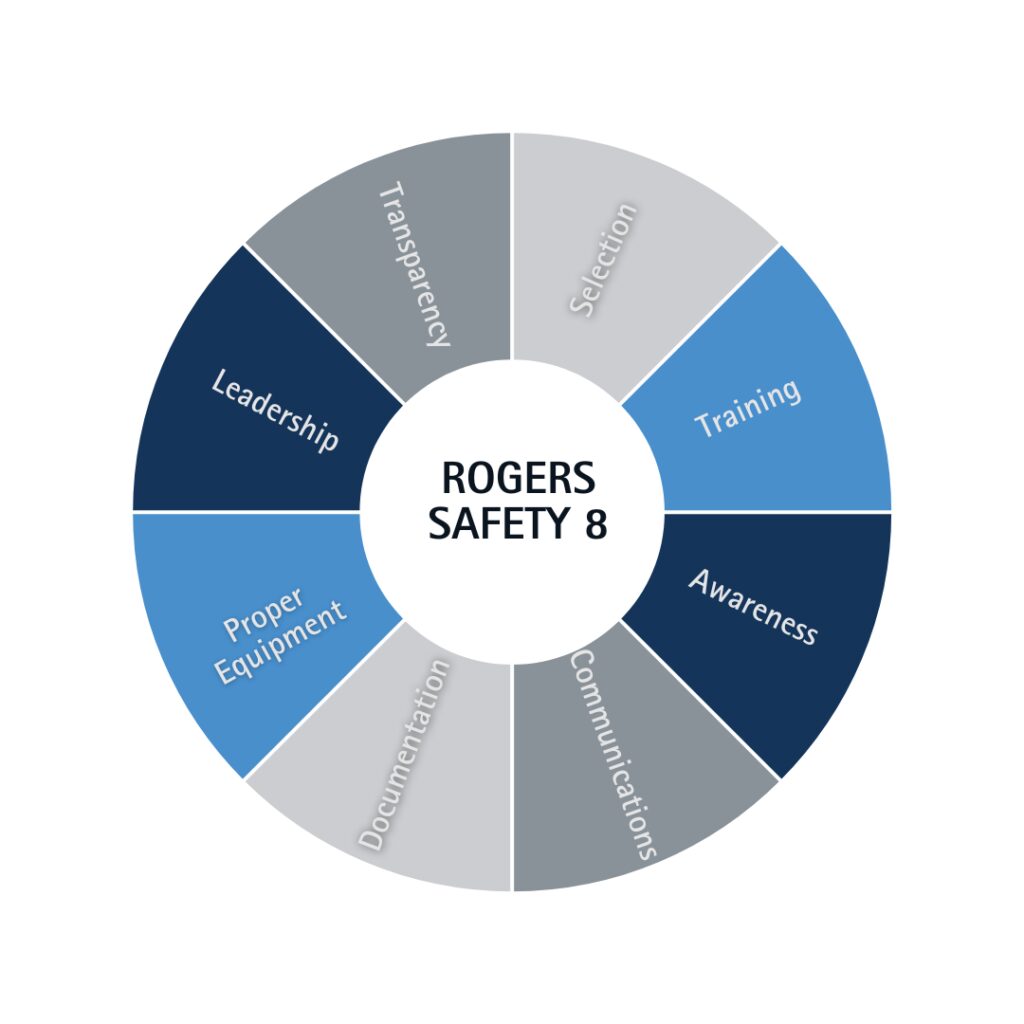

At the core of our operations is a commitment to safety. We accomplish this through initiatives like the Safety 8 program and Operational Risk Management (ORM). Prioritizing safety not only safeguards our employees and clients but also enhances operational efficiency, allowing us to accomplish tasks with minimal risk.

The Rogers 8 Safety Program ensures that all safety protocols are met.

Source: Rogers Electric

Rogers 8 Safety Program

The Rogers Safety 8 program explains why we have seen the lowest MOD and Incident rates in company history after implementation. The process demonstrates how we select our commercial electricians, train them to understand proper safety skills, and bring awareness to possible hazards they may encounter on the job site.

Once on site, we establish the importance of communication among team members to discuss goals and activities that will reduce any surprises that cause bodily harm. It is important that anything that occurs on site must be documented by Rogers employees to reinforce job expectations and safety. Additionally, proper PPE gear and equipment is essential for onsite safety. Lastly, strong leadership and transparency among the team is key to ensuring that all safety protocols are achieved.

At the core of Rogers Safety is our pre planning process for Operational Risk Management (ORM). Following this process will increase the probability for an accident-free job. Tasks and responsibilities are more clearly defined when ORM is used and safer decisions are made.

ORM is specified as the following: 1) Define the scope of work 2) Analyze the hazards 3) Develop and implement hazard controls 4) Perform work within hazard controls 5) Provide feedback and continuous improvement

Personal Protective Equipment

There are three different levels of Personal Protective Equipment (PPE) that commercial electricians use to minimize hazards when working with any source of electrical power. It is crucial when working with electrical equipment and open circuits that the proper equipment is worn to prevent injuries. Electrical hazards that may occur include, but are not limited to, electrical shocks and burns, arc flash burns and impacts, and other potential electrical safety hazards.

Level 1: Includes safety glasses, hard hat, work gloves, safety vest, and the proper steel-toed work boots.

This is the minimum uniform that is required at all job sites, regardless of the scope of the job. At Rogers Electric, long pants and a blue Rogers shirt is also required for any form of electrical service. It is essential that every commercial electrician follows this standard in order to prevent any injury.

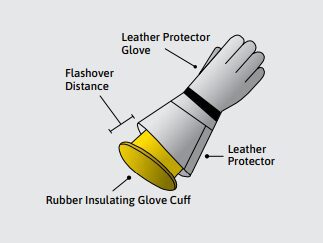

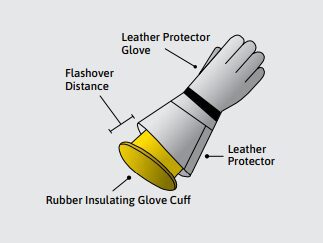

Level 2: Rubbers and leathers

This PPE gear is used when troubleshooting any circuit below and up to 30 amp. The leather gloves provide insulation against heat and protection against cuts and punctures. The leather gloves are worn on top of rubber gloves to ensure that the hands are sufficiently protected.

Rubber insulating gloves combined with leather protectors adequately protect the hands.

Source: Ansell

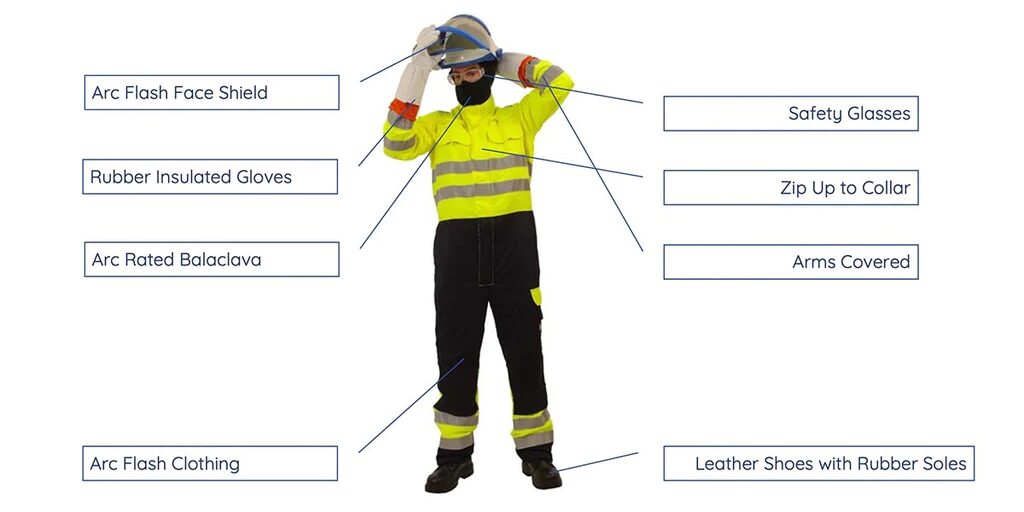

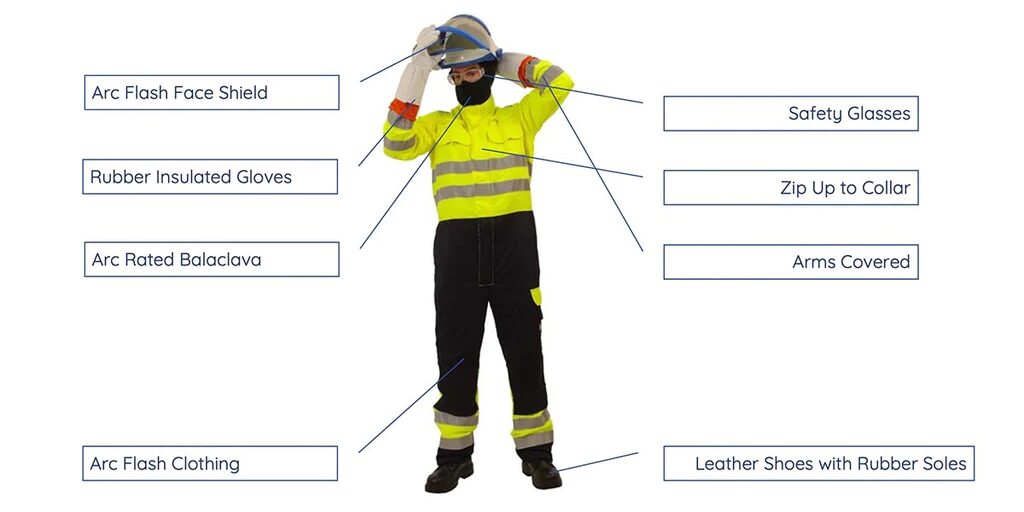

Level 3: Full PPE Gear (Arc Flash Suit )

Arc Flash PPE gear is used when working on an energized conductor that could possibly cause an electric arc. Anytime when testing a circuit above 30 amp, it is safe to say that an arc flash suit should be worn as a precaution. Not wearing enough PPE gear can expose an electrician to lethal injuries. On average, there are about 30,000 arc flash incidents every year that result in about 400 fatalities.

The Arc Flash Suit includes flame resistant pants and jacket, balaclava, rubber gloves, safety glasses, and face shield. It is necessary that every part of the gear is worn in order for the suit to be effective in protecting the electrician from arc flash risk.

Proper arc flash suit gear is required when testing energized circuits.

Source: Skanwear

Lockout Tagout

At Rogers Electric, we enforce a strict lockout tagout procedure (LOTO) for all of our commercial electricians. This procedure is necessary to enable and disable any machinery and equipment.

Using this method helps commercial electricians protect themselves from exposure to any hazardous energy. The purpose is to prevent and control hazardous electrical energies from becoming a risk. Using this LOTO method prevents an estimated 50,000 injuries and 120 fatalities each year.

Electrical Safety

In summary, securing a safe electrical environment takes a lot of preparation, planning, and process creation to ensure that every person on the team is on the same page. At Rogers Electric, the safety of our qualified electricians is paramount, driven by a sincere commitment to ensuring they return home safely to their families each day. Ensuring that safety measures are communicated effectively is something we pride ourselves on.

Wiring for success starts with a safety connection. Check out our Safety page to learn more.