Illuminate Savings: Cutting Costs with Smart Lighting

Explore the benefits of smart lighting—lower energy bills, fewer maintenance costs, and a greener future. Partner with Rogers Electric for smarter upgrades.

Read MoreWhat is predictive maintenance and why is it so important in this day and age? Businesses are rushing to create strategies that keep their facilities safe and efficient.

Many have found that the anticipatory nature of predictive maintenance allows for less downtime in facilities. And for manufactures consistently dealing with complex systems, this maintenance strategy is the optimal choice for dealing with assets.

Looking to improve your facilities management processes? Need some guidance when building out such a complex process for your business? Join us as we dive into the process of building a predictive maintenance strategy.

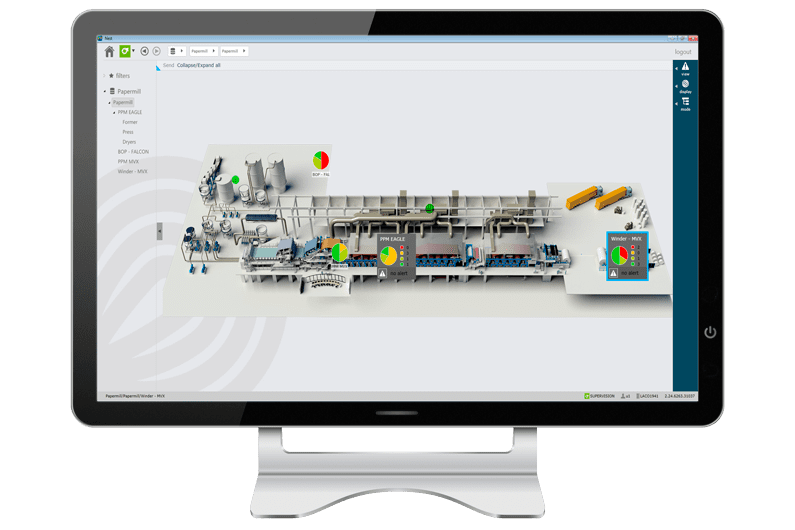

The internet of things allows for this strategy to work. It connects devices together to predict conditions before they happen.

The internet of things integrates sensors to acquire real-time analytics and allow for data analysis for the future. It can also be connected with AI software to perform even more proactive decisions.

The data processing through devices is a key step to performing a predictive maintenance strategy. Because of this, it is important to invest in IoT software sensors. Investing in the easy transfer of data from device-to-device will make your maintenance process easier. These sensors can detect faults through analysis of the systems.

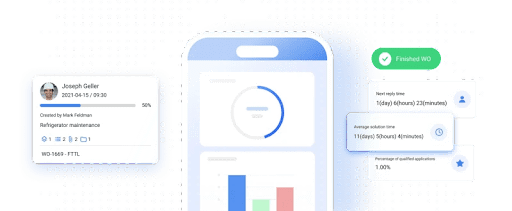

A company’s computerized maintenance management information system collects data from all assets of a company. It can include asset management, labor management, work orders, and much more.

It is important to integrate your preventative maintenance software into the CMMS. This allows for a one-stop shop of all maintenance and facilities needs. It creates a higher level of accessibility. This step also makes action plans much easier for when a repair needs to occur.

Using a CMMS is important when managing facilities. In fact, 78% of CMMS users have reported substantial improvements to their equipment life.

The brand Fracttal allows for easy integration of IoT software into its computerized maintenance management system. It lets the user plan with IoT information from their desktop or mobile phone. You can monitor and control equipment from anywhere on this system. Software like this is continuously making maintenance management easier for those that use it.

Once these IoT sensors are installed. They will create a model that will set parameters for a normal running system. If the system, for any reason, goes outside of these parameters, an alert will be triggered for facility management. This initial process can be timely but it is an important step to ensure accurate predictions.

This is where a company needs to plan for maintenance. If an alert is triggered it should be taken care of in a timely manner so that any sort of system failure can be avoided. Having a company like Rogers Electric by your side can reduce the headache of when these triggers hit.

We at Rogers Electric create long term and dependable relationships with clients so that we can be your first call in electrical repair emergencies. But, our commercial electricians are also highly experienced when it comes to preventative electrical maintenance.

If these sensors are not set up correctly, they could predict the wrong amount or type of maintenance. Companies should be sure to check up on these sensors every few weeks to ensure optimum use.

Regular facility maintenance processes should include regularly checking up on these systems.

We want to make sure that we are reacting to actual triggers so our actions are helpful to facilities. Integration of new technology can be tricky at first, but if done correctly it can save time, money, and energy.

Predictive maintenance can reduce maintenance costs, protect assets, increase machine life, as well as improve safety for employees.

With large upfront costs, predictive maintenance can seem daunting to some businesses. If efficiency and risk avoidance is your #1 priority, those costs are absolutely worth it. This strategy will undoubtedly save money in the long term.

The market for predictive maintenance is predicted to grow to $23.5 billion in a year. Companies are keen to invest in smart technology like this because of the long-term economical benefits.

Eighty percent of large manufacturers use predictive maintenance due to the type of equipment they work with. Size of facility is also a factor when deciding on investing in this tool. The larger your business, the more need you will have for this type of strategy.

Compared to reactive maintenance, predictive maintenance has a lot more long-term benefits. Especially when you are partnered with a resourceful and experienced commercial electrician.

No matter how large or complex your business model is, Rogers Electric can help. We have a wide range of experience at different types of facilities, big and small.

Our commercial electricians work hard to establish beneficial relationships with clients. Clients trust Rogers to be their first call when put in a tough spot. Whatever the trigger is, Rogers Electric will be there for all your preventative or emergency electrical maintenance needs.

Check out our previous projects to see the broad scope of electrical maintenance that we have performed in the past and continue to perform.